Dropsa

Dropsa

Lubrication Systems Solutions Specialists

- Главная

- О нас

- Решения

По сектору промышленности

По сектору промышленности- Сельскохозяйственное оборудование

- Энергия

- Цементные заводы и переработка сырья

- Пищевая промышленность

- Станки, Металлообработка и Прессы

- Sawing machines

- Прессы

- Судоходство и предбрежье

- Горнорудная промышленность и строительство

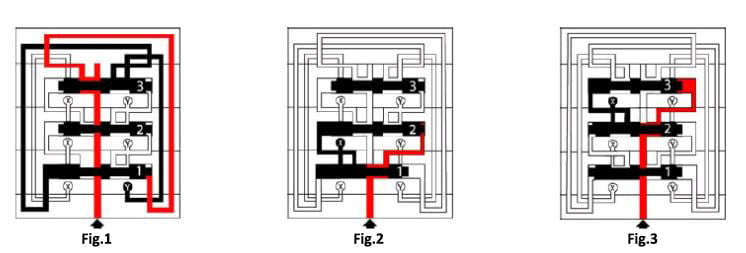

MQL: Обработка с минимальным количеством смазки

MQL: Обработка с минимальным количеством смазки Другие специальные приложения

Другие специальные приложения- Бумажная и деревообрабатывающая промышленность

Железнодорожные пути

Железнодорожные пути- Сталь и алюминий

Транспорт - оборудование и инфраструктура

Транспорт - оборудование и инфраструктура Текстиль

Текстиль

По типу смазки

По типу смазки

- Примеры применения

Каталог компонентов

Каталог компонентов Насосы

Насосы Распределители смазки

Распределители смазки Инжекторы и ограничители

Инжекторы и ограничители Коллекторы

Коллекторы Фитинги

Фитинги Жесткие и гибкие трубы и аксессуары

Жесткие и гибкие трубы и аксессуары Контроллеры

Контроллеры Система смазки минимальным количеством (MQL)

Система смазки минимальным количеством (MQL) Системы воздушно-масляной

Системы воздушно-масляной  Системы смазки масляным туманом

Системы смазки масляным туманом Специальные изделия

Специальные изделия Клапаны

Клапаны Распылители и форсунки

Распылители и форсунки Щетки

Щетки Фильтры

Фильтры Резервуары

Резервуары Комплектующие

Комплектующие Смазочные и расходные материалы

Смазочные и расходные материалы Датчики и контрольно-измерительные устройства

Датчики и контрольно-измерительные устройства

- Бланк контакта

- Blog